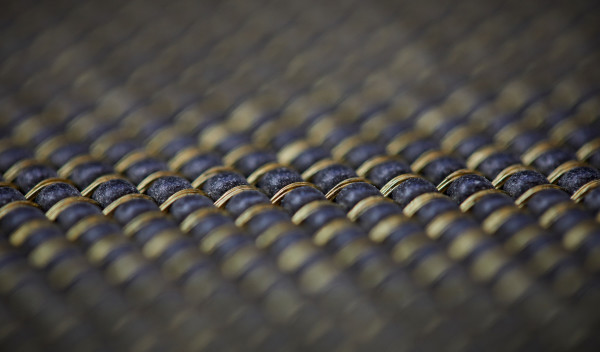

Pressure compensating pads are used widely throughout the laminate manufacturing industry.

Marathon produce a wide range of press pads, currently available with thicknesses ranging from 1.5 mm to 2.3 mm. No restriction to the thickness that could be made available.

In general terms, a thicker (and sometimes heavier) press pad may be required if you are looking to achieve a higher standard of finish.

Other factors that may affect your choice with regard to thickness and weight might be board density, the specific pressure being applied during the production process, unequal platens, and/or the condition of the press plates being used.

For example, if press platens are not parallel it would be wise to choose a thicker and/or heavier pad, as this would accommodate any inaccuracies between the press plate and the heated platen.

We recommend that you seek advice from your press pad supplier before making a final decision about the thickness and weight of pressure compensating pads that you purchase. This will avoid costly product rejects, failed production runs, quality issues and other manufacturing problems down the line.

Want to know more about how we can help you to optimise the press pad design for your specific laminate board process? We are look forward to your call.

For further information please contact us on:

Telephone: +44 1706 657052

Email: sales@marathonbelting.co.uk

![]()

Advanced performance textiles for industrial applications

Go BackGet in touch with Marathon