We very rarely come across customers involved in laminate board production that don’t use press pads.

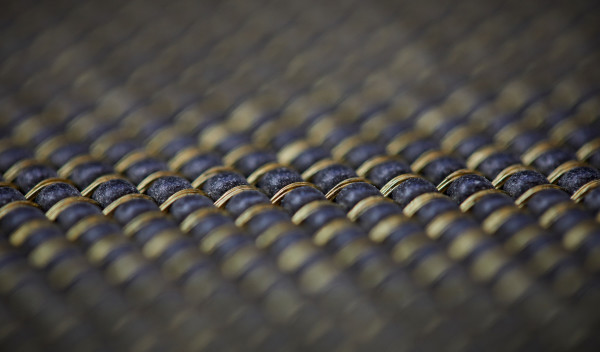

We would like to demonstrate how our unique design of press pad can help you to improve product quality, reduce rejects and help your production output to run at maximum capacity.

Many of our clients confirm that since using Marathon’s press pads, they can reduce cycle times when ancillary processing will allow; others prefer to reduce platen temperatures.

We have also had many end users who have been able to reduce cycle times, as well as platen temperatures.

A combination of the above is a huge advantage to productivity processes and general board quality. We know that the quality of the finished product is, to a large extent dependent, on equal heat and pressure distribution to the board surface.

Press pads are used between the heating platens and the press plates for 2 key reasons:

1) They ensure that the total board area being pressed receives equal pressure to compensate for any tolerance differences in the press, press plates and substrates.

2) Allows a fast and uniform heat transfer from the heating platens to the press plate surface.

For further information please contact us on:

Telephone: +44 1706 657052

Email: sales@marathonbelting.co.uk

![]()

Advanced performance textiles for industrial applications

Go BackGet in touch with Marathon