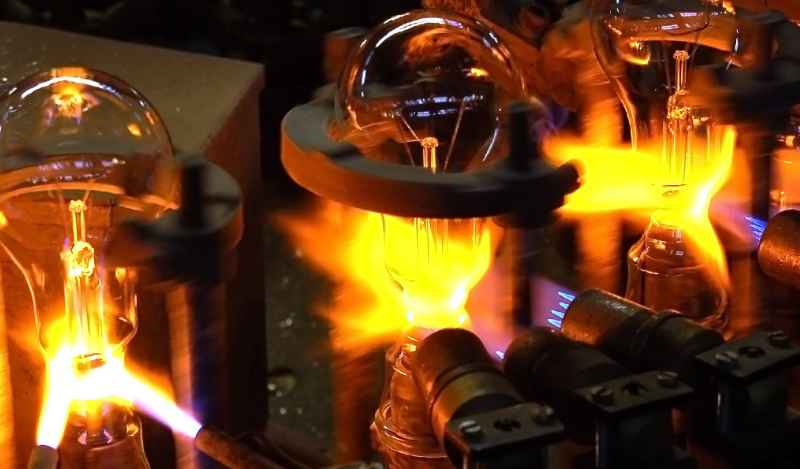

Over the years the use of steel conveyor belts for processing delicate glass articles such as tableware, cosmetic bottles and light bulbs has been challenged by new, improved higher temperature woven textile fabrics. But are they as cost effective, durable and reliable in practice? Marathon summarise the benefits of their Triton (Aramid/PAN) and PBO textile fabrics.

Triton by Marathon is a high temperature technical textile fabric manufactured to withstand temperatures of approximately 450°C. Triton conveyor belts have been used at higher temperatures than 450°c but increased carbonisation can take place, together with a reduction in strength over time leading to premature failure of the belt.

Triton can also be supplied in an impregnated format as fabricated wear pads. The chemical treatment of Marathon’s textile products is inorganic and environmentally benign, which increases the contact temperature capabilities of Triton to approximately 500°C. In this semi-rigid format, it is used as a facing material in applications such as push-bars and contact wear pads.

PBO materials have a temperature resistance in excess of aramid yarns and will not start to decompose until an air temperature of 650°C is reached.

With a light impregnation such as that used for Triton, it is often used to clad wipe out arms, guide bars, and when woven in tubular form, as sleeves for metal rollers. It is also supplied for conveying pressed glass articles.

Many think they are, especially where fine, delicate glass items are being processed.

Marathon Belting can also provide short lead times, local technical support and an excellent, speedy delivery service.

Don’t forget that textile belts (in comparison to steel belts) are often easier to repair and require little maintenance over time. This can be a real benefit for busy factories struggling to meet their production schedule.

TABLE

Marathon Belting is a world-class, performance textiles business. Our technical textile product solutions are used for demanding applications in multiple industries across the world. We are up for a challenge, so if you have one, please contact us by telephone on 01706 657052.

Advanced performance textiles for industrial applications

Go Back

Get in touch with Marathon